Combo heat press machines are versatile‚ multi-functional tools designed for various printing tasks. They offer interchangeable platens‚ compatibility with multiple materials‚ and different attachments for enhanced versatility and efficiency.

1.1 Overview of Combo Heat Press Functionality

A combo heat press machine is a multi-functional tool designed for various printing and heat transfer tasks. It supports interchangeable heat platens‚ allowing users to work with different materials like T-shirts‚ caps‚ mugs‚ and more. The machine features digital temperature and time controls‚ ensuring precise settings for optimal results. With modular attachments‚ it adapts to specific tasks‚ such as sublimation‚ screen printing‚ or specialty transfers. Its versatility makes it ideal for both small-scale crafts and bulk production. The machine operates by applying heat and pressure to transfer designs onto materials‚ with indicators guiding the process. This functionality ensures efficiency and consistency across various projects‚ making it a valuable asset for crafters and professionals alike. The combo heat press is a comprehensive solution for diverse printing needs‚ offering ease of use and high-quality outcomes.

1.2 Key Features of Combo Heat Press Machines

Combo heat press machines boast several standout features that enhance their functionality. One of their key attributes is the interchangeable heat platens‚ which allow users to switch between different sizes and types of platens for various projects. This modular design ensures versatility‚ catering to a wide range of materials and applications. Additionally‚ these machines often come with digital temperature and time controls‚ enabling precise adjustments for optimal results. Many models feature a robust build with durable components‚ ensuring long-lasting performance. Compatibility with multiple attachments further expands their utility‚ making them suitable for tasks like sublimation‚ screen printing‚ and specialty transfers. The inclusion of indicators for temperature and time provides real-time monitoring‚ while the compact design saves workspace. These features collectively make combo heat press machines a valuable investment for both hobbyists and professionals‚ offering efficiency‚ adaptability‚ and high-quality outcomes.

1.3 Compatibility with Different Materials and Attachments

Combo heat press machines are designed to work with a wide variety of materials‚ including fabrics‚ ceramics‚ glass‚ and metal‚ making them ideal for diverse projects. They are compatible with attachments tailored for specific tasks‚ such as T-shirt printing‚ mug heating‚ and cap pressing. The machine’s versatility allows it to accommodate different sizes and shapes of materials‚ ensuring precise and even heat distribution. Additionally‚ interchangeable attachments enable users to customize their workflow for specialized applications‚ such as sublimation printing or embroidery. The compatibility of these machines with multiple materials and attachments makes them a versatile tool for both hobbyists and professionals‚ catering to a broad range of creative and industrial needs. This adaptability ensures that users can achieve high-quality results across various mediums without the need for multiple machines.

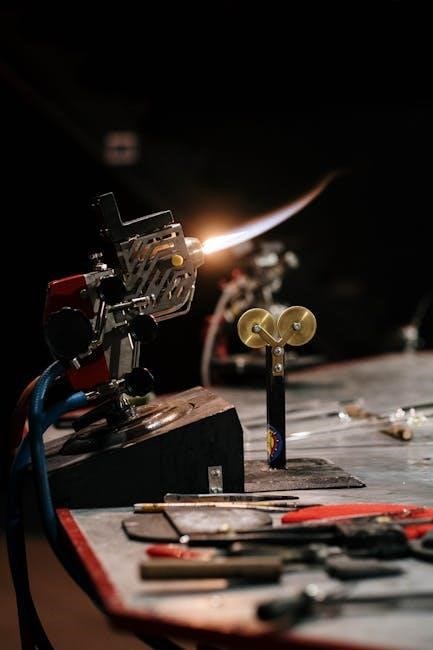

Installation and Setup of the Combo Heat Press

The installation process involves unboxing and inspecting the machine‚ preparing a safe workspace‚ connecting the device‚ and testing its components to ensure proper functionality before first use.

2.1 Unboxing and Initial Inspection

When unboxing your combo heat press machine‚ carefully inspect the package for any visible damage. Ensure all components‚ such as the power cord‚ heat platens‚ and pressing accessories‚ are included. Check for dents‚ scratches‚ or misaligned parts that may affect performance. Verify the machine’s compatibility with your workspace‚ ensuring proper ventilation and a stable surface. Familiarize yourself with the control panel and indicators‚ as outlined in the manual. Before powering on‚ confirm that all parts are securely attached and functioning correctly. If any issues are found‚ contact the manufacturer or supplier immediately. Proper inspection ensures safe and efficient operation‚ preventing potential malfunctions during use. Always refer to the manual for specific guidance on handling and preparing your machine for first-time use.

2.2 Preparing the Workspace for Safe Operation

Before operating the combo heat press machine‚ ensure your workspace is clean‚ flat‚ and heat-resistant. Clear the area of clutter‚ flammable materials‚ and liquids to minimize fire risks. Place the machine on a stable‚ even surface away from direct sunlight or moisture. Ensure proper ventilation to prevent the buildup of fumes from inks or coatings. Keep a fire extinguisher nearby for emergencies. Organize your workspace with essential tools‚ such as gloves‚ a heat-resistant mat‚ and a timer‚ within easy reach. Secure any loose cables or cords to avoid tripping hazards. Familiarize yourself with the machine’s dimensions to ensure adequate space for opening and closing the press. Always wear protective gear‚ including heat-resistant gloves‚ to safeguard against burns. A well-prepared workspace ensures safe‚ efficient‚ and high-quality results when using your combo heat press machine.

2.3 Connecting and Testing the Machine

Connect the combo heat press machine to a suitable power source‚ ensuring the voltage matches the machine’s specifications. Turn on the power and observe the control panel for lights or sounds indicating it is operational. Set the desired temperature and time using the control panel‚ then press start to initiate the heating process. The SET indicator will activate‚ and the display will show the current temperature; Once the set temperature is reached‚ the TIME indicator will begin the countdown. During this process‚ monitor the machine to ensure it heats evenly and maintains the set temperature. Perform a test run without materials to confirm proper function. If any issues arise‚ refer to the manual for troubleshooting steps. Always ensure the machine is preheated correctly before use to achieve optimal results. Proper testing ensures safe and efficient operation of your combo heat press machine.

Operating the Combo Heat Press Machine

Operate the combo heat press by setting temperature‚ time‚ and pressure via the control panel. Start the heating process and monitor progress through indicators and the digital display.

3.1 Understanding the Control Panel and Indicators

The control panel of a combo heat press machine is designed for easy operation. It typically features a digital display showing the current temperature‚ set temperature‚ and timer. Key indicators include the SET indicator‚ which lights up when the machine starts heating‚ and the TIME indicator‚ which activates once the desired temperature is reached and begins the countdown. These indicators ensure precise control over the heating process. Additional buttons or controls allow users to adjust temperature settings‚ start or stop the machine‚ and monitor the progress of the pressing cycle. Familiarizing yourself with the control panel and its indicators is essential for achieving optimal results in your printing tasks.

3.2 Setting Temperature‚ Time‚ and Pressure

Setting the correct temperature‚ time‚ and pressure is crucial for achieving professional results with your combo heat press. The temperature should be adjusted based on the material you are working with‚ typically ranging from 200°F to 400°F. For example‚ cotton fabrics usually require 300-350°F‚ while polyester and heat-sensitive materials need lower temperatures. The timer should be set according to the manufacturer’s guidelines‚ with most applications requiring 10-30 seconds for pre-pressing and 2-5 minutes for final pressing.

Pressure settings vary depending on the thickness of the material and the desired finish. Light pressure is ideal for delicate items‚ while firmer pressure is better for thicker fabrics or bulk orders. Always test the settings on scrap material first to ensure optimal results without damaging your work. Adjusting these parameters carefully ensures a flawless finish and prevents overheating or under-heating of the design.

3.3 How to Use Interchangeable Heat Platens

Interchangeable heat platens are a key feature of combo heat press machines‚ allowing you to adapt to various projects. To use them‚ start by ensuring the machine is turned off and has cooled down slightly to avoid burns. Remove the current platen by releasing the locking mechanism‚ usually located on the sides or top of the machine. Carefully lift the platen and set it aside on a heat-resistant surface. Next‚ align the new platen with the machine’s base‚ ensuring it fits securely into the designated slots. Tighten the locking mechanism to hold it in place. Always refer to the machine’s manual for specific platen sizes and compatibility. Once installed‚ test the platen by running a small‚ non-vital material through the press to ensure proper alignment and heat distribution. This feature allows you to switch between platens for different materials or designs effortlessly.

Pro Tip: Keep your platens organized and clean to maintain optimal performance and extend their lifespan.

3.4 Attaching and Detaching Pressing Accessories

Attaching and detaching pressing accessories on a combo heat press machine is straightforward but requires attention to detail. Always ensure the machine is turned off and cooled slightly before making any adjustments. To attach an accessory‚ align its mounting points with the corresponding slots on the press. Secure it using the provided clips‚ screws‚ or locking levers‚ depending on the machine’s design. Tighten firmly to prevent movement during operation. For detaching‚ reverse the process by loosening the securing mechanism and carefully lifting the accessory away. Always refer to the manual for specific instructions‚ as designs may vary. Keep accessories clean and dry to ensure proper function and longevity. Regularly inspect attachments for wear and tear to maintain optimal performance.

Pro Tip: Store accessories in a dedicated case or container to avoid misplacement and damage.

3.5 Starting the Heating Process and Monitoring Progress

To start the heating process‚ ensure all settings are correctly configured. Turn on the machine using the power switch and allow it to preheat to the desired temperature. Use the control panel to monitor the temperature gauge and timer. Once the preheat indicator light turns off or an audible beep sounds‚ the machine is ready for use. Always close the heat platens firmly to ensure even pressure distribution. During operation‚ monitor the timer and progress indicators to avoid overheating or underheating. When the cycle completes‚ carefully open the platens and inspect the result. For continuous use‚ repeat the process as needed‚ adjusting settings if necessary. Always prioritize safety by wearing heat-resistant gloves and keeping the area clear of flammable materials.

Pro Tip: Preheating the press before adding materials saves time and ensures consistent results.

Maintenance and Care for the Combo Heat Press

Regularly clean the heat platens‚ lubricate moving parts‚ and perform routine checks to ensure optimal performance and longevity of the machine.

4.1 Cleaning the Heat Platens and Surfaces

Regular cleaning of the heat platens and surfaces is essential to maintain the combo heat press machine’s efficiency and prevent residue buildup. Start by turning off the machine and allowing it to cool completely to avoid burns. Use a soft‚ dry cloth to wipe down the platens‚ removing any debris or ink residue. For stubborn stains‚ lightly dampen the cloth with distilled water or a mild detergent solution‚ but avoid harsh chemicals or abrasive cleaners that could damage the surfaces. Clean the surrounding areas‚ including the frame and controls‚ with a damp cloth. Never use bleach or acidic substances‚ as they may harm the machine’s finish. After cleaning‚ dry all surfaces thoroughly with a clean towel to prevent rust or water spots. Regular maintenance ensures optimal heat distribution and extends the machine’s lifespan. Always refer to the manual for specific cleaning recommendations tailored to your model. Proper care prevents damage and ensures consistent performance. Regular cleaning also helps maintain hygiene and prevents the transfer of unwanted substances during pressing. By keeping the heat platens and surfaces clean‚ you ensure precise temperature control and even pressure distribution‚ which are critical for achieving professional-quality results. Additionally‚ inspect the platens for scratches or wear and address them promptly to avoid affecting your projects. Cleaning is a simple yet crucial step in maintaining the functionality and longevity of your combo heat press machine. Stay consistent with this routine to enjoy reliable operation and superior outcomes in all your heat pressing tasks. This practice not only preserves the machine but also enhances your overall user experience. Remember‚ a clean machine is a productive machine. Always prioritize cleanliness to safeguard your investment and ensure uninterrupted creativity. Cleaning is an integral part of responsible machine ownership and a key factor in achieving exceptional results. Regularly scheduled cleaning sessions will keep your combo heat press in prime condition‚ ready to handle any project you undertake. This proactive approach minimizes downtime and maximizes efficiency‚ making it a vital habit for all users. By incorporating cleaning into your routine‚ you protect your machine and ensure it continues to perform at its best for years to come. A well-maintained combo heat press is not just a tool; it’s a reliable partner in your creative or production processes. Cleaning is a simple yet effective way to demonstrate care for your equipment and commitment to quality. Make it a priority to clean your machine regularly and reap the benefits of consistent‚ high-quality performance. This attention to detail ensures that every press is precise‚ and every project meets your expectations. Cleaning is more than maintenance—it’s an investment in your success. Keep your combo heat press clean‚ and it will continue to deliver the results you trust. Regular cleaning sessions are a cornerstone of responsible machine ownership‚ ensuring longevity and reliability. By staying on top of this task‚ you safeguard your equipment and maintain peak performance. Cleaning is a straightforward process that yields significant benefits‚ making it an essential part of your routine. Prioritize cleanliness today and enjoy a hassle-free experience with your combo heat press machine tomorrow. A clean machine is not only more efficient but also safer to use‚ reducing the risk of accidents caused by residue buildup. Cleanliness plays a dual role in both performance and safety‚ making it a critical aspect of machine care. Stay vigilant about cleaning to protect your investment and ensure a safe working environment. Regular cleaning is a simple yet powerful practice that directly impacts the functionality and safety of your combo heat press. Incorporate it into your maintenance routine for a seamless and productive experience. A clean machine is a happy machine‚ and a happy machine delivers outstanding results every time. Cleaning is an effortless way to show your combo heat press the care it deserves‚ ensuring it remains a trusted companion in your creative journey. By keeping your machine clean‚ you foster a productive and efficient workflow‚ allowing you to focus on what matters most—creating exceptional products. Cleaning may seem like a small task‚ but its impact on the performance and longevity of your combo heat press is immense. Dedicate a few minutes to this process‚ and your machine will reward you with years of reliable service. A clean combo heat press is not just well-maintained; it’s also a testament to your dedication to quality and professionalism. Make cleaning a habit‚ and your machine will continue to be a valuable asset in your projects. Regular cleaning is a proactive measure that prevents issues before they arise‚ ensuring your combo heat press operates smoothly and efficiently. By prioritizing cleanliness‚ you eliminate potential problems and extend the life of your machine. This simple practice is a cornerstone of effective machine maintenance and a key to achieving consistent‚ high-quality results. Cleaning is an essential step in the proper care of your combo heat press‚ and neglecting it can lead to subpar performance and premature wear. Stay proactive by incorporating regular cleaning into your routine‚ and your machine will thank you with unparalleled reliability. A clean machine is a reliable machine‚ and a reliable machine is indispensable in any production or craft setting. By keeping your combo heat press clean‚ you ensure it remains a vital tool in your creative process. Cleaning is a fundamental aspect of machine maintenance that should never be overlooked. It not only preserves the integrity of your equipment but also guarantees the quality of your work. Regular cleaning sessions are a small price to pay for the long-term benefits they provide. Make cleanliness a priority‚ and your combo heat press will continue to serve you faithfully‚ project after project. This simple yet crucial practice is a testament to your commitment to excellence and your machine’s continued performance. A clean combo heat press is more than just a well-maintained tool; it’s a reflection of your dedication to producing outstanding results. By cleaning regularly‚ you honor your machine and elevate the quality of your work. Cleaning is a simple act that speaks volumes about your professionalism and care for your equipment. Keep your combo heat press clean‚ and it will continue to be your most trusted ally in achieving your creative and production goals. Regular cleaning is a powerful way to ensure your machine remains in top condition‚ ready to tackle any challenge you throw its way. By prioritizing cleanliness‚ you empower your combo heat press to perform at its best‚ delivering results that exceed your expectations. A clean machine is a happy machine‚ and a happy machine is one that consistently produces exceptional outcomes. Cleaning is a small but significant investment in the performance and longevity of your combo heat press. Make it a habit‚ and your machine will reward you with years of faithful service. Regular cleaning is a cornerstone of responsible machine ownership‚ ensuring your combo heat press remains a reliable and indispensable tool in your workflow. By staying on top of this task‚ you protect your investment and maintain the quality of your work. A clean combo heat press is not just a machine; it’s a partner in your success. Keep it clean‚ and it will continue to help you achieve your goals with precision and excellence. Cleaning is a simple yet effective way to show your combo heat press the care it needs to perform at its best. By incorporating this practice into your routine‚ you ensure your machine remains a vital asset in your creative or production processes. A clean machine is a productive machine‚ and a productive machine is one that helps you succeed. Regular cleaning is a proactive step that safeguards your combo heat press and ensures it continues to deliver the results you depend on. By prioritizing cleanliness‚ you protect your investment and maintain the high standards of your work. A clean combo heat press is a testament to your professionalism and commitment to quality. Make cleaning a priority‚ and your machine will remain a trusted companion in all your projects. Regular cleaning is a small effort that yields big rewards in terms of performance and longevity. By keeping your combo heat press clean‚ you ensure it remains a reliable and essential tool in your workflow. Cleaning is a simple practice that makes a significant difference in the functionality and lifespan of your machine. Incorporate it into your maintenance routine‚ and your combo heat press will continue to serve you faithfully. A clean machine is a happy machine‚ and a happy machine is one that consistently delivers exceptional results. By prioritizing cleanliness‚ you empower your combo heat press to perform at its best‚ ensuring every project meets your high standards. Regular cleaning is a fundamental aspect of machine care that should never be overlooked. It not only preserves the integrity of your equipment but also guarantees the quality of your work. By staying vigilant about cleaning‚ you protect your investment and maintain

4.2 Lubricating Moving Parts for Smooth Operation

Lubricating the moving parts of your combo heat press machine is crucial for ensuring smooth and quiet operation. Identify the hinges‚ gears‚ and other mechanical components that require lubrication. Use a high-quality‚ heat-resistant silicone-based spray lubricant‚ as it won’t leave residue or attract dust. Apply a light coat to the moving parts‚ then wipe off any excess with a clean‚ dry cloth to prevent drips or mess. Avoid using oil-based lubricants‚ as they may degrade under high temperatures. Lubricate every 3 to 6 months or when you notice increased friction or noise. Regular lubrication prevents wear and tear‚ reduces noise‚ and ensures consistent pressure and alignment. Always turn off and allow the machine to cool before lubricating to avoid accidents. Proper lubrication maintains optimal performance and extends the lifespan of your combo heat press. Keep the machine running smoothly by incorporating lubrication into your maintenance routine. Regular lubrication is a simple yet effective way to preserve the functionality and longevity of your equipment. By addressing moving parts‚ you ensure seamless operation and prevent potential issues down the line. Lubrication is a key factor in maintaining the efficiency and reliability of your combo heat press. Make it a priority to keep your machine well-lubricated for consistent results. This practice not only enhances performance but also protects your investment‚ ensuring your combo heat press continues to serve you effectively. Regular lubrication is a proactive step that safeguards against mechanical stress and promotes smooth operation. By staying on top of this task‚ you ensure your machine remains in excellent working condition. Lubricating moving parts is a straightforward process that yields significant benefits‚ making it an essential part of your maintenance routine. Keep your combo heat press running smoothly with regular lubrication and enjoy uninterrupted productivity. This simple maintenance practice is vital for maintaining the machine’s performance and longevity. Always use the right lubricant and follow proper techniques to ensure the best results. Lubrication is a small effort that makes a big difference in the overall functionality of your combo heat press. By prioritizing this task‚ you protect your machine and ensure it continues to deliver exceptional performance. Regular lubrication is a cornerstone of responsible machine ownership‚ ensuring your combo heat press operates smoothly and efficiently. Make it a habit to lubricate moving parts‚ and your machine will reward you with years of reliable service. A well-lubricated machine is a productive machine‚ and a productive machine is one that helps you achieve your goals. Keep your combo heat press in prime condition by incorporating lubrication into your maintenance schedule. This simple practice is a testament to your commitment to quality and longevity. By lubricating regularly‚ you ensure your machine remains a trusted tool in your creative or production processes. Regular lubrication is a powerful way to enhance the performance and lifespan of your combo heat press. Make it a priority‚ and your machine will continue to serve you faithfully‚ project after project. This proactive approach minimizes downtime and maximizes efficiency‚ making it a vital habit for all users. By incorporating lubrication into your routine‚ you protect your investment and ensure uninterrupted creativity. Lubricating moving parts is more than maintenance—it’s a way to demonstrate care for your equipment and commitment to excellence. Keep your combo heat press well-lubricated‚ and it will continue to be your most trusted ally in achieving your creative and production goals. Regular lubrication is a small but significant investment in the performance and longevity of your machine. By staying on top of this task‚ you ensure your combo heat press remains a reliable and indispensable tool in your workflow. A well-lubricated machine is not just well-maintained; it’s also a reflection of your professionalism and dedication to quality. Make lubrication a habit‚ and your machine will remain a vital asset in your projects. Regular lubrication is a simple yet effective practice that directly impacts the functionality and longevity of your combo heat press. Incorporate it into your maintenance routine for a seamless and productive experience. A well-lubricated machine is a happy machine‚ and a happy machine delivers outstanding results every time. Lubrication may seem like a small task‚ but its impact on the performance and lifespan of your combo heat press is immense. Dedicate a few minutes to this process‚ and your machine will reward you with years of reliable service. A well-lubricated combo heat press is not just well-maintained; it’s also a testament to your dedication to quality and professionalism. Make lubrication a habit‚ and your machine will continue to be a valuable asset in your projects. Regular lubrication is a proactive measure that prevents issues before they arise‚ ensuring your combo heat press operates smoothly and efficiently. By prioritizing lubrication‚ you eliminate potential problems and extend the life of your machine. This simple practice is a cornerstone of effective machine maintenance and a key to achieving consistent‚ high-quality results. Lubrication is an essential step in the proper care of your combo heat press‚ and neglecting it can lead to subpar performance and premature wear. Stay proactive by incorporating regular lubrication into your routine‚ and your machine will thank you with unparalleled reliability. A well-lubricated machine is a reliable machine‚ and a reliable machine is indispensable in any production or craft setting. By keeping your combo heat press well-lubricated‚ you ensure it remains a vital tool in your creative process. Lubrication is a fundamental aspect of machine maintenance that should never be overlooked. It not only preserves the integrity of your equipment but also guarantees the quality of your work. Regular lubrication sessions are a small price to pay for the long-term benefits they provide. Make lubrication a priority‚ and your combo heat press will continue to serve you faithfully‚ project after project. This proactive approach minimizes downtime and maximizes efficiency‚ making it a vital habit for all users. By incorporating lubrication into your routine‚ you protect your investment and ensure uninterrupted creativity. Lubrication is more than maintenance—it’s a way to demonstrate care for your equipment and commitment to excellence. Keep your combo heat press well-lubricated‚ and it will continue to be your most trusted ally in achieving your creative and production goals. Regular lubrication is a small but significant investment in the performance and longevity of your machine. By staying on top of this task‚ you ensure your combo heat press remains a reliable and indispensable tool in your workflow. A well-lubricated machine is not just well-maintained; it’s also a reflection of your professionalism and dedication to quality. Make lubrication a habit‚ and your machine will remain a vital asset in your projects. Regular lubrication is a simple yet effective practice that directly impacts the functionality and longevity of your combo heat press. Incorporate it into your maintenance routine for a seamless and productive experience. A well-lubricated machine is a happy machine‚ and a happy machine delivers outstanding results every time. Lubrication may seem like a small task‚ but its impact on the performance and lifespan of your combo heat press is immense. Dedicate a few minutes to this process‚ and your machine will reward you with years of reliable service. A well-lubricated combo heat press is not just well-maintained; it’s also a testament to your dedication to quality and professionalism. Make lubrication a habit‚ and your machine will continue to be a valuable asset in your projects. Regular lubrication is a proactive measure that prevents issues before they arise‚ ensuring your combo heat press operates smoothly and efficiently. By prioritizing lubrication‚ you eliminate potential problems and extend the life of your machine. This simple practice is a cornerstone of effective machine maintenance and a key to achieving consistent‚ high-quality results.

and Additional Resources

4.3 Regular Maintenance Checks and Updates

Regular maintenance checks and updates are essential to ensure the combo heat press machine operates at its best. Schedule routine inspections every 1 to 3 months‚ depending on usage. Check electrical connections for wear or damage‚ and replace any frayed cords or loose plugs. Inspect the heat platen alignment to ensure even pressure distribution and adjust if necessary. Update firmware or software periodically to access new features and improvements. Clean or replace air filters if applicable to maintain proper airflow. Inspect and tighten all bolts and screws to prevent loosening over time. Keep a maintenance log to track inspections and updates. Addressing potential issues early prevents unexpected downtime. Regular checks also help identify worn-out parts‚ such as heat-resistant pads or insulation‚ which should be replaced promptly. Follow the manufacturer’s guidelines for specific maintenance tasks. By staying proactive‚ you ensure the machine remains efficient and reliable over time.