Safety Guidelines

Always follow the manual’s safety guidelines to ensure safe operations․ Ensure the jig is assembled correctly to avoid accidents during use․

Use appropriate router bits to prevent damage and maintain control․ Keep children away from the work area and regularly inspect the equipment for wear․

1․1․ Important Safety Instructions

Always read and follow the manual thoroughly before using the Porter-Cable dovetail jig․ Ensure proper assembly of the jig to prevent accidents during operation․ Use only recommended router bits to maintain control and avoid damage to the equipment or workpiece․ Keep loose clothing and long hair tied back to avoid entanglement with moving parts․ Wear safety goggles and a dust mask to protect against debris and dust․ Keep children and pets away from the work area to minimize distractions and risks․ Regularly inspect the jig and router for wear or damage‚ and replace worn parts immediately․ Avoid overreach and maintain a firm grip on the router to ensure precise control during cutting operations․ Never leave the jig unattended while in use‚ and always unplug the router when making adjustments or changing bits․ Follow all safety guidelines provided in the manual to ensure safe and effective operation of the dovetail jig․

1․2․ Additional Specific Safety Rules

In addition to general safety guidelines‚ specific rules apply when using the Porter-Cable dovetail jig․ Always unplug the router before making adjustments or changing bits to prevent accidental start-ups․ Use the correct template guides for the type of dovetail being cut to ensure accuracy and safety․ Never exceed the recommended material thickness specified in the manual‚ as this can cause damage to the jig or router․ Keep the workpiece securely clamped to prevent movement during cutting‚ which could lead to inaccurate cuts or accidents․ Avoid using damaged or worn-out bits‚ as they can cause uneven cutting and loss of control․ Always maintain a clean work area to prevent tripping hazards and ensure proper visibility; Follow the manual’s instructions for setting up and operating the jig to minimize risks and achieve professional results․

1․3․ Background Information

The Porter-Cable dovetail jig is a precision tool designed to help woodworkers create accurate and professional-looking dovetail joints․ With a long history of innovation‚ Porter-Cable has established itself as a trusted brand in woodworking․ The dovetail jig is part of a comprehensive system that includes routers‚ template guides‚ and specialized bits‚ all working together to simplify the process of cutting dovetails․ Originally introduced in the early 2000s‚ the jig has evolved over the years‚ with models like the 4112 and 4216 becoming popular among both professionals and hobbyists․ Its durability and versatility make it a favorite for projects ranging from furniture making to cabinet construction․ By following the manual’s instructions‚ users can achieve consistent results and master the art of dovetail joinery․

1․4․ Emergency Procedures

In case of an emergency while using the Porter-Cable dovetail jig‚ immediately turn off the router and disconnect the power supply․ If a bit breaks or the jig malfunctions‚ do not attempt to remove debris while the tool is in operation․ Always wear protective gear‚ including safety glasses and gloves‚ to minimize injury risk․ If the jig becomes misaligned or unstable‚ stop the operation and carefully realign the components before resuming․ For severe mechanical issues‚ refer to the manual or contact Porter-Cable support for assistance․ Never touch sharp edges or moving parts during or after an emergency․ Proper adherence to these procedures ensures safety and prevents further damage to the equipment or workpiece․

Setting Up the Porter-Cable Dovetail Jig

Begin by unboxing and inventorying all components․ Carefully assemble and align the jig according to the manual․ Install the dovetail bit and template guides securely․ Adjust the jig for your material’s thickness and prepare the workpiece for precise dovetail cutting․

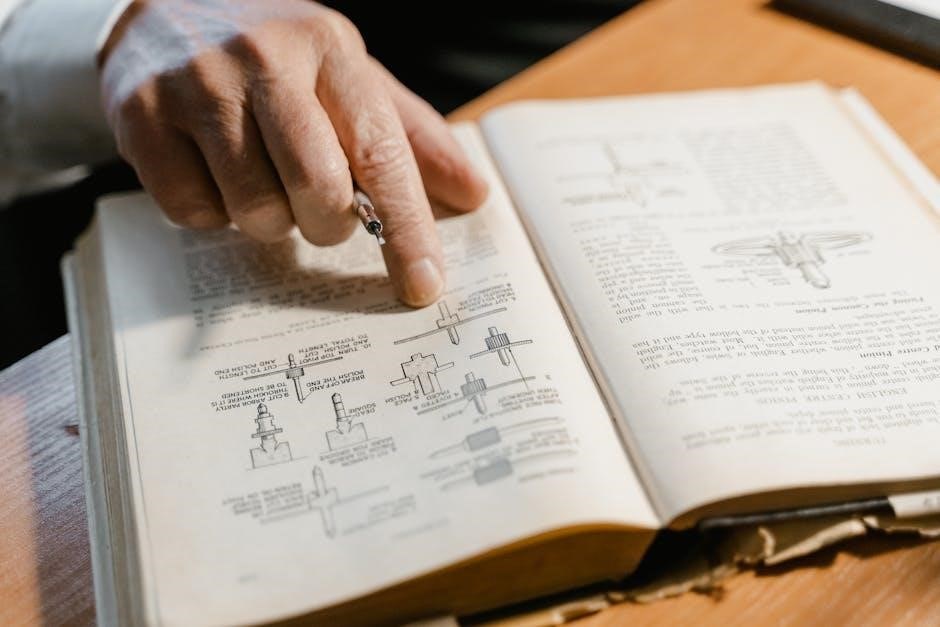

2․1․ Unboxing and Inventory of Components

Start by carefully unboxing the Porter-Cable dovetail jig and inspecting all included components․ Ensure the package contains the dovetail fixture‚ router bits‚ template guides‚ and edge guide sets․ Verify that all parts are undamaged and account for any accessories listed in the manual․ Familiarize yourself with each component’s purpose‚ such as the dovetail bit for cutting joints and the template guides for alignment․ Organize the parts on a clean work surface to avoid misplacement․ Refer to the inventory list in the manual to confirm completeness․ This step is crucial for ensuring proper assembly and operation of the jig․ Take note of any additional items required for setup‚ such as a router or clamps‚ and gather them before proceeding․

2․2․ Assembly and Alignment of the Jig

Begin by attaching the dovetail fixture to a sturdy work surface using the provided clamps or screws․ Ensure the jig is securely fastened to prevent movement during operation․ Next‚ align the template guides with the edge of your workpiece‚ using the edge guide sets for precise positioning․ Refer to the manual for specific alignment instructions based on your project’s requirements․ Use a router to test the alignment and ensure proper registration with the template․ Adjust the template guides as needed to achieve accurate dovetail joints․ Double-check all alignments before proceeding to cutting․ Proper assembly and alignment are critical for achieving professional-quality results with the Porter-Cable dovetail jig․

2․3․ Installing the Dovetail Bit and Template Guides

To install the dovetail bit‚ first remove the straight bit from the router․ Securely attach the dovetail bit using the provided wrench‚ ensuring it is tightly fastened․ Next‚ locate the template guides and attach them to the router according to the jig’s specifications․ Align the guides with the dovetail template‚ ensuring proper registration․ Use the edge guide sets to position the template accurately․ Tighten all connections firmly to prevent movement during cutting․ Double-check the alignment and fit of the bit and guides before proceeding․ Proper installation ensures precise dovetail cuts and optimal performance of the jig․ Refer to the manual for specific torque settings and alignment instructions to guarantee accuracy and safety․

2․4․ Adjusting the Jig for Different Material Thicknesses

To adjust the jig for different material thicknesses‚ begin by measuring the material using a thickness gauge․ Loosen the adjustment knobs on the jig to allow movement of the template guides․ For 1/2-inch material‚ position the guides at the first mark‚ and for 3/4-inch material‚ move them to the second mark․ Ensure the guides are aligned with the material’s edge for accurate cuts․ Tighten the knobs securely after adjustment․ Always refer to the manual for specific measurements and markings․ Proper alignment ensures flush cuts and precise dovetail joints․ Double-check the setup before cutting to avoid errors․ This feature allows versatility in handling various material sizes‚ enhancing the jig’s functionality for different projects․

2․5․ Preparing the Workpiece for Dovetail Cutting

Before cutting dovetails‚ ensure the workpiece is properly prepared․ Measure and mark the areas where the dovetail joints will be cut‚ using a pencil and straightedge․ Square the edges of the workpiece to ensure accurate alignment with the jig․ Lightly sand the surfaces to remove any splinters or imperfections․ Use clamps to secure the workpiece firmly to the jig‚ ensuring it doesn’t move during the cutting process․ Align the jig with the marked lines‚ double-checking the positioning for accuracy․ Proper preparation is crucial for achieving clean‚ precise dovetail joints․ Always follow the manual’s guidelines for specific setup instructions tailored to your project’s requirements․

Operating the Porter-Cable Dovetail Jig

Align the router with the template guides and ensure proper bit installation․ Use edge guides for accurate half-blind and through dovetail cuts․ Follow manual instructions for smooth operation․

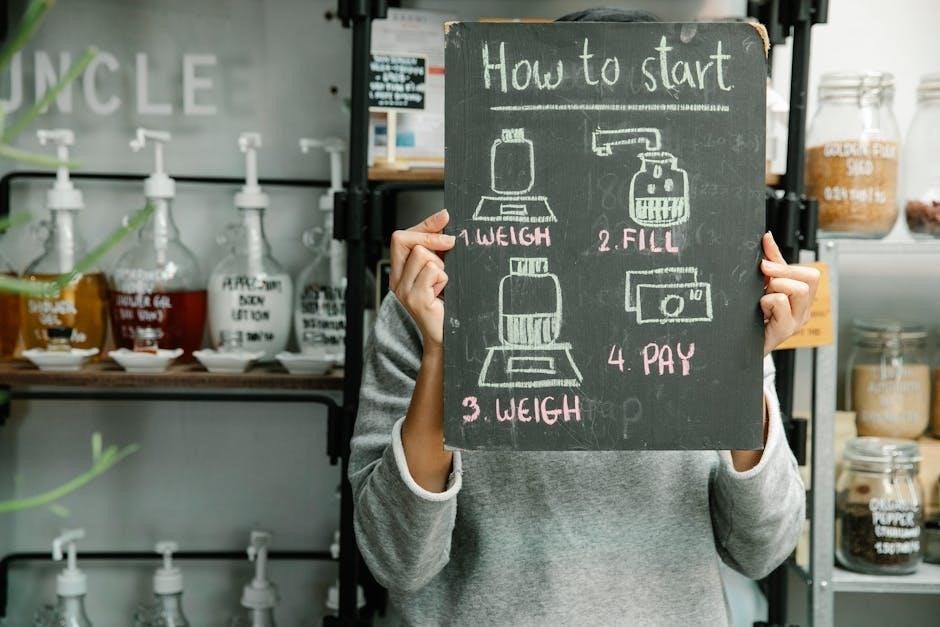

3;1․ Basic Dovetail Jig Operations

Begin by aligning the router with the template guides and ensuring the dovetail bit is properly installed․ Clamp the workpiece securely to the jig‚ making sure it is flush with the guide edges․ For half-blind dovetails‚ position the jig according to the manual’s instructions and make a test cut to verify alignment․ Use the edge guides to maintain accuracy and consistency․ Always feed the router at a steady‚ controlled pace to avoid uneven cuts․ After completing the cuts‚ inspect the joints for proper fit and adjust the jig if necessary․ Practice on scrap material before working on final projects to refine your technique․ Refer to the manual for specific settings and guidelines tailored to your project’s requirements․

3․2․ Cutting Half-Blind and Rabbeted Half-Blind Dovetails

For half-blind dovetails‚ position the workpiece so the dovetail joint will be hidden on one side․ Use the edge guide set specifically designed for half-blind cuts․ Clamp the material firmly to the jig‚ ensuring proper alignment with the template guides․ Install the dovetail bit and adjust the router to the recommended depth․ Make a test cut on scrap material to verify accuracy before cutting the actual workpiece․

For rabbeted half-blind dovetails‚ follow similar steps but include a rabbet cut along the edge of the workpiece․ Use the rabbeting bit first‚ then switch to the dovetail bit for the joint․ Always maintain steady control of the router and ensure the jig remains stable during operation․ Refer to the manual for specific depth and alignment settings for these cuts to achieve professional results․

3․3․ Through Dovetail Operations and Techniques

Through dovetail operations involve cutting joints that are visible from both sides of the material․ To achieve this‚ remove the dovetail bit and template guide from the router‚ then install a straight bit․ Position the workpiece on the jig‚ ensuring proper alignment with the template guides․ Clamp securely to prevent movement during cutting․ Make a single pass through the jig to create the through dovetail joint․ For wider materials‚ multiple passes may be required‚ adjusting the router depth incrementally․ Always use a backup board to prevent tear-out on the exit side․ Maintain steady control of the router and ensure consistent feed rates for clean‚ precise cuts․ This technique is ideal for applications requiring maximum strength and visibility‚ such as drawer construction or shelf joints․

Maintenance and Troubleshooting

Regularly clean and lubricate the jig to ensure smooth operation․ Inspect for wear and store in a dry place․ Replace worn parts as needed for optimal performance․

4․1․ Cleaning and Lubricating the Jig

Regularly clean the jig to remove dust and debris using a soft brush or cloth․ Avoid harsh chemicals‚ as they may damage the finish․ Lubricate moving parts with a light oil to maintain smooth operation․ Inspect and clean the template guides and dovetail bit after each use to ensure accuracy․ Wipe down the jig with a dry cloth before storage to prevent rust․ Check for wear on bushings and other components and replace them if necessary․ Proper maintenance will extend the life of the jig and ensure consistent performance․ Always follow the manufacturer’s recommendations for cleaning and lubrication products․ Store the jig in a dry‚ secure location to protect it from damage when not in use․

4․2․ Storing the Jig and Accessories

Store the Porter-Cable dovetail jig and its accessories in a dry‚ clean environment to prevent rust and damage․ Use the original case or a sturdy storage box to protect the jig and components․ Organize small parts‚ such as template guides and bits‚ in labeled compartments to avoid loss․ Keep the jig away from direct sunlight and moisture to maintain its finish․ Before storage‚ ensure all parts are clean and free from debris․ Check for wear on accessories and replace worn items if necessary․ Store the router and bits separately in protective cases․ Label the storage container for easy identification․ Proper storage will help maintain the jig’s performance and extend its lifespan․ Always follow the manufacturer’s storage recommendations for optimal results․

4․3․ Common Issues and Solutions

Common issues with the Porter-Cable dovetail jig often relate to misaligned cuts or uneven joints․ Ensure the template guides are properly secured and aligned with the workpiece․ If cuts are uneven‚ check the dovetail bit for dullness or damage and replace it if necessary․ Incorrect router speed can also cause poor results; consult the manual for recommended settings․ For sticking or binding‚ lightly lubricate the moving parts with silicone spray․ If the jig vibrates excessively‚ ensure it is firmly clamped to a stable work surface․ Regularly cleaning debris from the jig and router bit can prevent performance issues․ For persistent problems‚ refer to the troubleshooting section in the manual or contact Porter-Cable customer support for assistance․ Always follow the manufacturer’s guidelines for resolving issues to maintain optimal performance․

4․4․ Replacing Worn or Damaged Parts

Regularly inspect the Porter-Cable dovetail jig for worn or damaged components‚ such as the dovetail bit or template guides․ If damage is found‚ replace parts immediately to maintain accuracy and safety․ Order genuine Porter-Cable replacement parts to ensure compatibility and performance․ Before replacing‚ unplug the router and ensure the jig is disconnected from power․ Follow the manual’s disassembly instructions to access the damaged part․ Replace the component securely‚ tightening all fasteners as specified․ After replacement‚ test the jig on scrap material to ensure proper function․ For complex replacements‚ consult the manual or contact Porter-Cable customer support for guidance․ Regular part replacement prevents performance issues and extends the jig’s lifespan․ Always prioritize safety and precision when performing repairs․

Accessories and Router Bits

The Porter-Cable dovetail jig is compatible with specialized router bits and template guides․ These accessories ensure precise cuts and are essential for creating accurate dovetail joints․ Use genuine Porter-Cable parts for optimal performance․

5․1․ Types of Dovetail Bits and Their Uses

Porter-Cable dovetail jigs utilize specific router bits designed for precise dovetail cuts․ The 14° dovetail bit is ideal for standard dovetail joints‚ offering strength and visibility․ For finer details‚ the 12° bit is recommended‚ creating narrower‚ more delicate joints․ The 10° bit is best for small-scale projects or intricate designs․ Additionally‚ straight bits are used for through dovetails‚ ensuring clean‚ flush cuts․ Each bit type is tailored for specific joint requirements‚ ensuring accuracy and versatility in woodworking projects․ Always use genuine Porter-Cable bits to maintain quality and compatibility with the jig system․ Proper bit selection enhances the performance of the dovetail jig and ensures professional-grade results․ Refer to the manual for bit recommendations based on your project needs․

5․2․ Template Guides and Edge Guide Sets

Template guides and edge guide sets are essential for accurate dovetail cuts with the Porter-Cable dovetail jig․ Template guides attach to the router‚ ensuring proper alignment with the jig’s templates‚ while edge guide sets help maintain straight edges and control during cutting․ The jig includes two edge guide sets: one for half-blind and one for rabbeted half-blind dovetails․ These guides are interchangeable‚ allowing flexibility for different project requirements․ Always secure the template guides firmly to the router to prevent movement during operation․ Proper alignment ensures precise cuts and professional-grade results․ Regularly inspect the guides for wear and replace them as needed to maintain accuracy․ Using genuine Porter-Cable accessories guarantees compatibility and optimal performance with the dovetail jig system․

Advanced Dovetail Jig Techniques

Master advanced techniques like custom dovetail joints and complex projects with precision; Experiment with unique configurations and materials for intricate designs‚ ensuring proper setup and tool maintenance for optimal results․

6․1․ Customizing Dovetail Joints

Customizing dovetail joints allows for unique and personalized woodworking projects․ By adjusting the jig’s setup‚ you can create varying angles‚ spacing‚ and configurations to suit specific design needs․ Experiment with different router bits and templates to achieve distinct joint styles‚ such as angled or curved dovetails․ For intricate designs‚ consider layering multiple joints or incorporating decorative elements; Proper alignment and precise measurements are crucial to ensure strength and aesthetics․ Practice on scrap material to refine techniques before working on final pieces․ Regularly maintain the jig and bits to ensure consistent results․ With creativity and skill‚ custom dovetail joints can elevate your woodworking projects to professional levels․

6․2․ Creating Complex Dovetail Projects

Creating complex dovetail projects requires precision and advanced techniques․ Start by designing your project‚ ensuring accurate measurements and alignment․ Use the Porter-Cable dovetail jig to cut intricate joints‚ leveraging its adjustability for varying material thicknesses․ For multi-drawer cabinets or intricate furniture‚ layer dovetail joints to enhance stability․ Experiment with angled or staggered dovetails for visual appeal․ Utilize specialized router bits‚ such as the 4200 or 4216 series‚ for clean‚ precise cuts․ Practice on scrap wood to refine your approach before tackling the final project․ Regularly inspect and maintain the jig to ensure consistent results․ With patience and skill‚ complex dovetail projects can showcase exceptional craftsmanship and functionality․